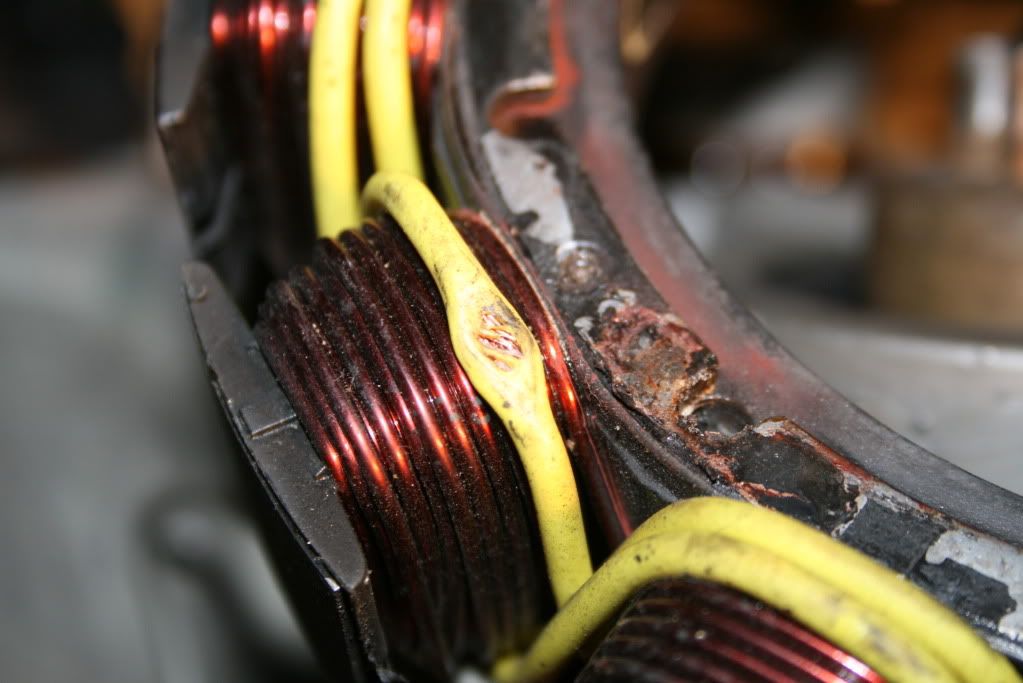

The stator will spike and take out the regulators. This is almost impossible to test for.

The 260's use a 16 amp system and have to rune everything you have except for the depth finders. Most electronics don't pull that many amps and will only start creating issues if you have a battery problem as 16 amps is enough to run the electric fuel pump, ecu, trim, and depth finders. If you have a weak battery that takes a lot to bounce back from starting, then it will seem like you have a charging issue when you don't. You would be surprised at how little that stuff draws. If you have a good multi-meter with the amp function, simply place it in line of the positive and it will tell you exactly how much it pulls when running. If you want to be 100% sure, move the electronics to the trolling motor batteries and keep the cranking battery load to a minimum. Of course this is MY opinions and experiences.